Let our team identify or engineer

the perfect solution for your application.

As we begin 2024, we are excited and inspired by the polymer industrial 3D printing space and what the future holds for our industry. In 2023, we saw applications like the Falcon Drone Bird, the Wilson Airless Basketball, and more, all with the common thread of material customization. We anticipate another revolutionary year in polymer 3D printing, and as material developers and manufacturers, we compiled a few industry predictions we see bubbling beneath the new year surface.

As we continue to strive towards more responsible manufacturing business practices and finding ways to reduce our collective carbon footprint, sustainability of materials has become a growing topic of discussion and continues to sway material sourcing decisions. For manufacturers using Nylon 12, a material made with petroleum, this means considering the switch to Nylon 11, a material made from 100% renewable castor beans. Bio-based materials such as Nylon 11 retain chemical and mechanical traits to Nylon 12 materials, while also providing manufacturers with a product that is climate neutral and reduces the overall carbon footprint of applications.

We predict these conversations surrounding material sustainability and responsible manufacturing practices will continue and grow, along with manufacturers examining the overall lifecycle of their products to find new and innovative ways to reduce the impact that plastic manufacturing has on our environment.

As technology innovation continues to bring us to new heights, industries such as drone manufacturing have soared. Drone Industry Insights reported the total drone investment value in the U.S. has nearly tripled from 2020 ($2.4 billion) to $7 billion in 2021. This trend has continued, funneling increased engineering power and ingenuity into the topic of compact, adept applications such as drones. Polymer 3D printing has served as a tool for accelerated prototyping in this rapidly developing industry and a material solution for weight, strength, and electrostatic discharge (ESD) requirements of drone components.

Materials with ESD capabilities will also be increasingly leveraged in drone and electronic equipment, as well as those in the consumer electronic space. As our history has shown with laptops, cell phones, and other consumer electronic equipment, smaller is better. And with less components, weight, and better design capabilities, 3D printing is poised to be the next tool in the evolution of consumer technologies.

Fire-resistant materials, such as ALM FR-106, were initially developed for applications within the aerospace industry. Aerospace manufacturers often require all applications to include a fire-resistant element due to the heat conductivity in aerospace equipment. While fire-resistant materials will always be in demand from the aerospace industry, we have seen an increase across other industries such as automotive and government laboratories as well. As material science and development continues to produce products that can be applied in more manufacturing processes, it opens the door for engineers to leverage AM within their own production lines.

Although it is easy to overlook material because of bucket classifications such as nylons, elastomers, etc., the performance of an end-use application begins and is determined by the material’s core capabilities. The more AM material development is explored and succeeds, the more industries AM will be able to penetrate and offer new manufacturing solutions to in the future.

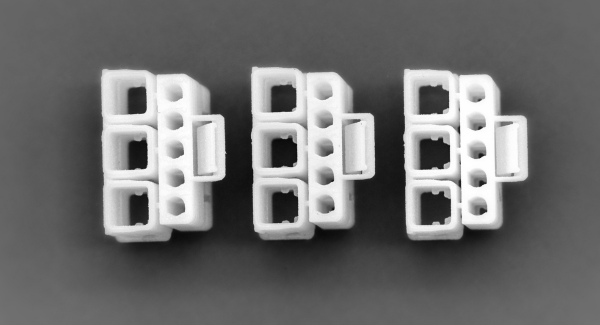

Stereolithography (SLA) has historically dominated the industry of fine detail polymer 3D printing, but with recent advancements in selective laser sintering (SLS) capabilities, the FORMIGA P 110 FDR system by EOS, we may see an increase in materials being developed for SLS FDR technology. As a sister company of EOS, ALM has always complemented the EOS polymer material portfolio, but remains system agnostic. This means that although we often are consulting with customers who use EOS systems, we are not beholden to material development exclusive to EOS technology.

With this new opportunity for unprecedented surface finish without post-processing and delicate part structures, we predict an increased demand for polymer AM materials compatible with FDR systems on the horizon. And, if you are one of the early adopters of FDR technology, ALM is already developing the materials you may be interested in leveraging with this AM advancement.

Let our team identify or engineer

the perfect solution for your application.