Let our team identify or engineer

the perfect solution for your application.

Dedicated to the advancement of selective laser sintering (SLS) polymer material development, ALM is here to help you match the right material to the right applications. Application performance begins with the material it is comprised of, leaning on the polymer’s properties to perform the functionalities of the end-use application.

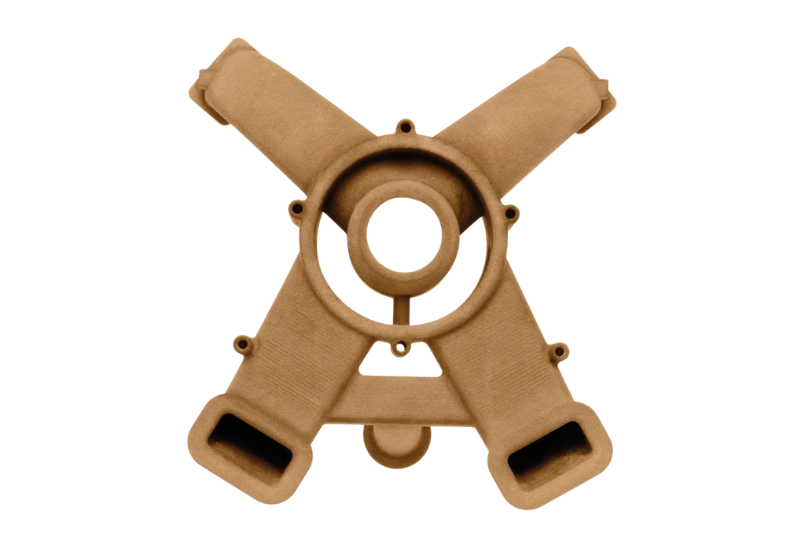

With over 30 materials in the ALM portfolio and beyond, selecting the right material for your project can seem daunting. To begin understanding the material options available, here are two materials that are currently trending in the polymer SLS space: PEKK 100 and HT-23. Both of these high-performance polymers are paving the way for innovations in aerospace, automotive, and industrial applications. Let’s dive into the unique properties and advantages of each material.

PEKK 100 is a remarkable material that serves as an effective substitute for injection-molded glass fiber-filled Polyamide 6 (PA 6 GF). Here are its standout benefits:

HT-23 is a high-performance polymer based on PEKK resin, reinforced with 23% carbon fiber. This material is designed for superior thermal and mechanical properties:

Both materials cater to a variety of industries:

PEKK 100

Automotive: Ideal for small-series production where injection-molded glass-fiber-filled PA 6 is commonly used.

Electrical and Electronics: Thanks to its insulation properties and flame retardancy, PEKK 100 is perfect for E&E applications.

Aerospace: Its high thermal and mechanical properties make it suitable for lightweight, high-strength components.

HT-23

PEKK 100 and HT-23 each offer unique benefits that cater to specific industry needs. As additive manufacturing continues to grow, these high-performance polymers will play a crucial role in developing innovative solutions across various sectors. By leveraging their advanced properties, manufacturers can create parts that not only meet but exceed the demands of modern applications.

Chat with an ALM team member today to learn more about the versatile and customized polymer materials available for your next 3D printed application.

Let our team identify or engineer

the perfect solution for your application.